A fire takes place in a structure every 63 seconds in the United States. A number of industries are more in danger to fires including transportation, energy, manufacturing, and other mission-critical surroundings. For businesses with a higher risk of fire, it is imperative to have the best fire protection system, like an automatic fire suppression system, to protect valuable equipment, minimize risk, and keep the workforce safe.

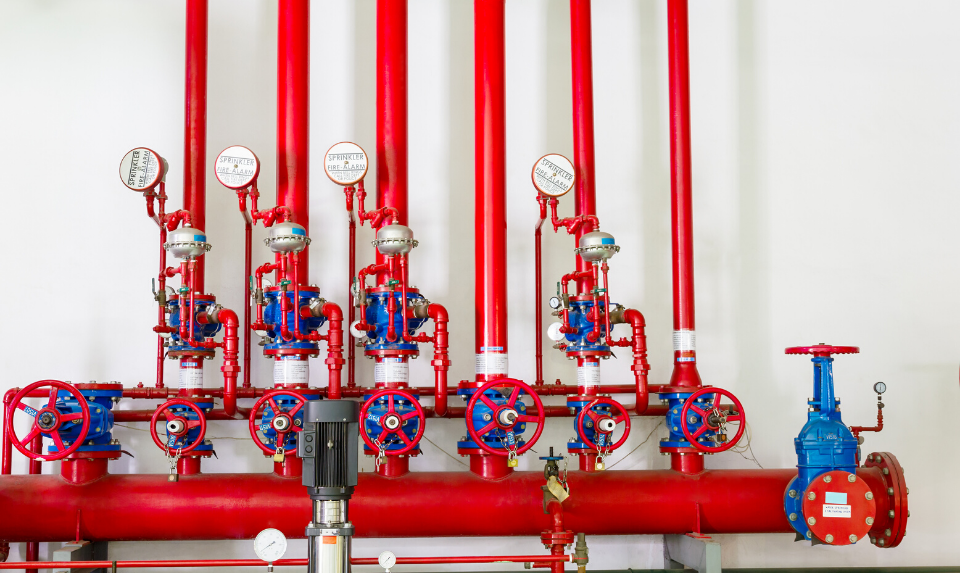

There are some options for fire suppression systems. One of the most familiar types is a fire sprinkler system that spreads water to suppress the fire. While this technique is very dependable, in a lot of applications water can do more damage than good as well as the damage caused to equipment.

This is also the case with automatic fire suppression systems that use water mist suppression agents. Water mist agents can cause deterioration and have ecological and health issues.

Another option is an automatic fire suppression system that uses dry chemical or gaseous chemicals to contain a fire. The advantage of the gaseous agents is it leaves no scum behind while the dry chemicals are applicable for applications with combustible and flammable liquids.

An automatic fire suppression system may be triggered manually or automatically when a fire is detected. This post explains the distinction between automatic fire containment systems and systems that involve human intervention.

Defining an Automatic Fire Suppression System

An automatic fire suppression system control and put out fires without human involvement. Examples of automatic systems consist of gaseous fire containment, condensed aerosol fire, and containment fire sprinkler system. When fires are put out in the early stages loss of life is minimal since 93% of every fire-related death takes place once the fire has developed beyond the early stages. Furthermore, automatic fire containment systems respond to a rapid rise in heat, or fire conditions, without any human involvement.

Types of Automatic Fire Suppression System

Nowadays there are several types of automatic fire containment systems and standards for each one. Systems are as different as a lot of applications. In general, on the other hand, an automatic fire suppression system has two categories: pre-engineered and engineered systems.

Pre-engineered fire containment systems use pre-designed elements to get rid of the need for engineering work clear of the innovative product design. Typical industrial solutions use a wet or dry chemical agent, for instance; mono-ammonium phosphate (MAP), or potassium carbonate to guard relatively smaller spaces like; wind turbines distribution boards, engine bays, hazardous goods, battery rooms, and other storage areas.

A number of housing designs have in addition emerged that typically utilize water mist and aim retrofit applications.

Engineered fire containment systems are created specific and most frequently used for larger installations where the system is designed for a particular application. Examples include public and private buildings, large marine and land vehicle applications, industrial paint lines, server rooms, electrical switch rooms, and dip tanks.

Engineered systems use a number of gaseous or solid agents with a lot of of them being purposely formulated. Some are even stored as a fluid and discharged as a gas.

Another kind of fire containment system relies on detection tubing set up inside the enclosed space to perceive the rising heat from a fire. As soon as a fire is identified, a pressure differential is made causing the tubing to break at the point of heat contact. When the tubing breaks it discharges pressure on the cylinder.

The fire containment agent is released from the cylinder into the area to contain the fire. Simultaneously the agent is discharged; a pressure switch will turn off any coolant pumps, machines, etc.

Some automatic fire containment systems in addition have a manual release for an individual to discharge the agent into the area. A manual release is usually installed when building specifications need a definite level of redundancy with the automatic system in the occasion of a breakdown.

When to Install an Automatic Fire Suppression System

Building codes and policy usually define where automatic fire containment systems have to exist. For instance, if there is an industrial complex storing fuel, there should be an OSHA condition saying an automatic fire containment system is required. There are arrays of other governing bodies that dictate the security within an organization.

These consist of NFPA, VDF, ISO, or the CCCF in Asia. While regulations may not constantly need automatic fire containment systems, some organizations choose to set up systems proactively to protect essential assets and avoid downtime.